- Flow Rate of Regenarate Solution: 17.6 – 26.4 gpm. (4 – 6 m/hr)

- Iodine Number, mg/g: 1000 (min)

- Ash, wt%: 4.0 (max)

- Moisture (As Packaged), wt%: 5 (max)

- Density (Apparent), g/cc: 0.48 (min)

- Hardness Number: 95 (min)

- 12 US Mesh [1.70 mm], wt%: 5 (max)

- < 40 US Mesh [0.425 mm] (PAN), wt%: 4 (max)

Aquatrol coconut shell granular activated carbon is a high quality coconut shell activated carbon for the removal of dissolved organic contaminants from water, wastewater and process liquids. The list of contaminants includes taste and odor compounds, organic color, total organic carbon (TOC) and industrial chemicals such as chlorinated solvents (PCE, TCE).

Aquatrol GAC is produced under controlled conditions through high temperature steam activation. Its pore structure enables it to be used for adsorption of both high and low molecule weight impurities from water and diverse liquids.

Aquatrol GAC is especially effective for adsorbing trace organic compounds such as vinyl chloride, MTBE, methylene chloride and Trihalomethanes/disinfection by-products. GCS-830 is certified to NSF/ANSI 61 standard and complies with the requirements for activated carbon as defined by the Food Chemicals Codex (FCC) (8th Edition) published by the U.S. Pharmacopeia.

DESIGN CONSIDERATIONS

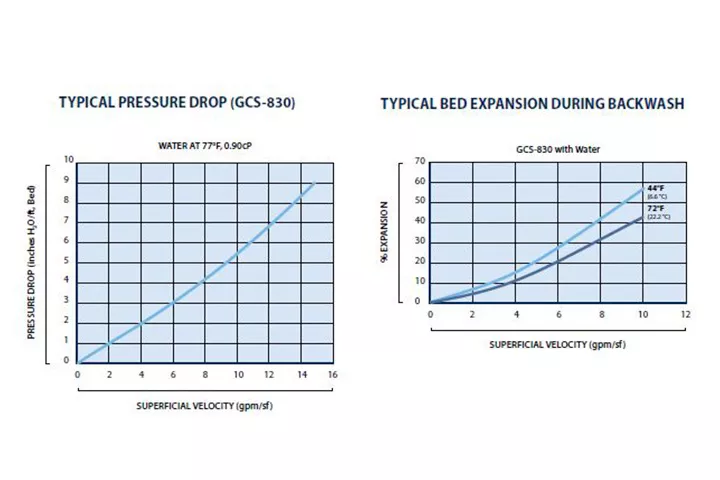

Aquatrol coconut shell activated carbon is typically applied in down-flow packed bed operations using both pressure and gravity systems. Design considerations for a carbon system should be based on the user’s operating conditions, treatment objectives desired, and the chemical nature of the compounds being adsorbed. Downflow superficial velocity can be from 1 gpm/ft2 to 10gpm/ft2, depending on the application.

APPLICATIONS

Aquatrol coconut shell activated carbon can be used in a variety of water, wastewater and process liquid applications for the removal of dissolved organic compounds. GCS-830 can be used in applications such as process water purification, wastewater treatment and industrial chemical purification.

FEATURES

- Coconut shell carbon

- High mechanical strength

- Low ash

BENEFITS

- Strong adsorbing pore structure optimal for the treatment of chlorine and other organics.

- Hardness and abrasion resistance required for thermal reactivation and minimizing fines when operations backwashing is required.

- Provides a wide range of contaminant removal capabilities.